Setting up a Direct to Film (DTF) T-shirt printing system requires specific equipment for high-quality prints, including a reliable DTF printer, plotter/cutter, heat presses, and accessories. This method produces vibrant colors on diverse fabrics using precise cutting and heat pressing, ideal for custom designs. Essential tools include precision cutters, measuring tools, templates, and heat presses for optimal print quality and efficient production, catering to individual orders or bulk manufacturing.

“Unleash your creativity with the art of DTF (Direct-to-Fabric) T-shirt printing! This guide equips you with all the essential knowledge and lists the equipment needed for a successful setup. From the core components like printers, plotters, and materials to additional tools for precision, we cover it all. Discover the key elements that transform your T-shirt design process, ensuring vibrant, lasting prints. Master the DTF printing system and take your custom apparel creation to new heights.”

- Essential Equipment for DTF Setup

- Key Components of the Printing System

- Additional Tools for Precise Results

Essential Equipment for DTF Setup

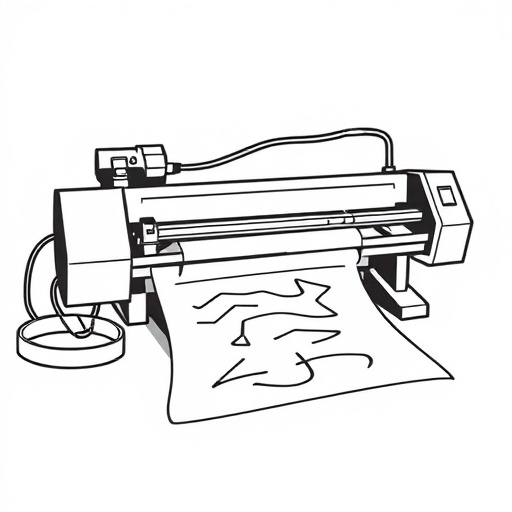

Setting up a DTF (Direct to Film) T Shirt Printing system requires specific equipment designed to ensure precise and high-quality prints. The core components include a reliable DTF printer, capable of producing detailed images directly onto transparent film. This is followed by a DTF plotter or cutter, which precisely cuts out the design from the film, ready for transfer to the t-shirt.

Additionally, you’ll need heat presses to apply the DTF transfer to the fabric, along with various accessories like squeegees, heat-resistant mats, and cleaning solutions. A stable workbench or station is also crucial for organization and ease of use. Remember, investing in high-quality equipment will directly impact your print outcomes, ensuring vibrant colors and crisp details on each DTF printing for t-shirts.

Key Components of the Printing System

The DTF (Direct-to-Fabric) T Shirt Printing system is a powerful tool for creating high-quality custom designs on various fabrics. Its key components include a reliable printer, cutting plotter, and a heat press machine. The best dtf printer should offer precise color reproduction and excellent image quality, ensuring your designs pop on both light and dark fabrics. When printing on darker garments, consider using cold peel DTF transfers, which provide a crisp finish and easy application.

Additionally, the cutting plotter plays a crucial role in preparing the transfer material by accurately cutting out the design to match the garment’s shape and size. A good heat press machine is essential for applying the DTF transfers onto fabrics smoothly and without bubbles or misalignments. Together, these components form the backbone of a successful DTF T Shirt Printing setup.

Additional Tools for Precise Results

For achieving precise and high-quality DTF T Shirt Printing results, additional tools play a pivotal role. These include precision cutting tools like craft knives or cutting pliers to ensure clean and accurate cuts around designs. Measuring tapes and rulers are essential for taking exact measurements of T-shirts, ensuring the printed design aligns perfectly with the garment’s shape and size. Additionally, a variety of templates and transfer paper in different sizes can facilitate the transfer of intricate designs onto various types and sizes of T-shirts, catering to both small-scale and bulk DTF T Shirt Printing needs.

Beyond these, heat presses or ironing boards are indispensable for applying heat during the printing process, fusing the ink firmly into the fabric, especially for DTF printing for light fabrics. These tools enable efficient production workflows, making it possible to manage both simple and complex designs in a timely manner. For those involved in DTF for Apparel, investing in these additional tools can significantly enhance overall print quality and streamline the production of high-demand items, whether for individual orders or bulk dft shirt production.

Setting up a DTF T-shirt printing business requires an investment in the right equipment. By understanding the essential components, key systems, and additional tools outlined in this article, you’re well on your way to achieving high-quality, precise DTF T-shirt printing results. With the right setup, you can create vibrant, durable designs that cater to a range of customer preferences, making your business a standout in the competitive world of custom apparel.