DTF (Direct to Film) T-shirt printing uses specialized printers to apply transfer films directly onto fabric for superior color accuracy and detailed imagery. Process involves digitally preparing designs, applying ink to transfer film, then aligning and heat pressing it to garments. This method ensures vibrant colors that last through washes, making it ideal for custom apparel and promotional items. Essential materials include DTF heat transfer paper, printing equipment, and design software. Precise cutting tools and the right transfer sheets maintain clean edges and color vibrancy, crucial for clothing brands preserving brand identity and customer satisfaction.

Discover the art of applying transfers in DTF (Direct to Fabric) T-shirt printing, a game-changer for creating vibrant designs. This guide takes you through the entire process, from setting up your workstation to mastering techniques for flawless results. Learn how to prepare your materials, ensure precise application, and achieve high-quality prints every time. Unlock the secrets to successful DTF T-shirt printing and elevate your creations to a new level.

- Understanding DTF Transfer Application Process

- Preparing Your Workstation and Materials

- Techniques for Precise and High-Quality Transfers

Understanding DTF Transfer Application Process

Understanding DTF Transfer Application Process

DTF (Direct to Film) T Shirt printing is a cutting-edge technique that allows for precise and vibrant designs on various fabrics, from light and delicate materials like cotton to robust items such as hoodies. The process involves using specialized equipment known as a direct to film printer to apply transfer films directly onto the fabric. This method offers numerous benefits, including superior color accuracy, detailed imagery, and the ability to print on curved surfaces or complex shapes.

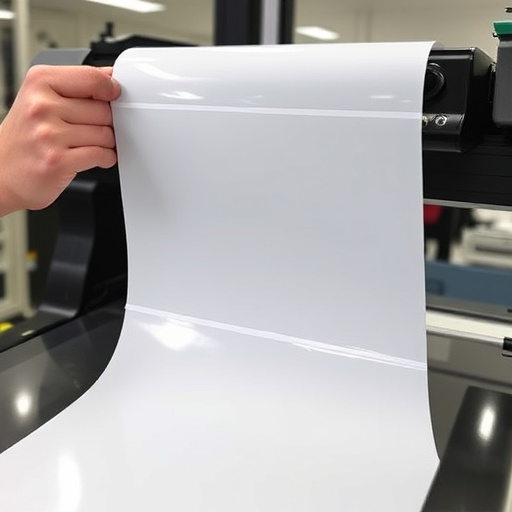

The DTF transfer application process starts with preparing the design digitally. Using graphic design software, the artwork is optimized for printing, ensuring it meets the required resolution and specifications. Once ready, the design is sent to the direct to film printer, which precisely jets ink onto a transfer film, creating a mirror image of the desired pattern or text. The film is then carefully aligned with the t-shirt or hoodie and heat pressed, fusing the design into the fabric. This meticulous approach ensures that colors remain rich and vibrant even after multiple washes, making DTF printing an excellent choice for both personal and commercial applications, including creating custom apparel, promotional merchandise, and more.

Preparing Your Workstation and Materials

Before you begin applying transfers with DTF (Direct to Fabric) T shirt printing, it’s essential to prepare your workstation and gather all necessary materials. Start by clearing a dedicated workspace, ensuring it is well-lit and clean to minimize distractions and mess. Gather your DTF for t-shirts, which typically includes specialized DTF heat transfer paper designed for apparel, along with your printing equipment such as a printer, heat press machine, and any additional tools like scissors or a roller.

Additionally, prepare your design software to ensure smooth transfer application. Ensure the image is correctly aligned and scaled on the t-shirt template. Double-check the quality of your design, as crisp lines and sharp details are crucial for successful DTF for apparel printing. Have your heat press set to the appropriate temperature and pressure settings recommended by the manufacturer for optimal DTF heat transfer paper adhesion.

Techniques for Precise and High-Quality Transfers

When it comes to DTF T Shirt Printing, achieving precise and high-quality transfers is essential for delivering outstanding results. One effective technique involves utilizing precision cutting tools that allow for exact trimming around designs, ensuring clean edges on the transferred image. This meticulous approach is particularly beneficial for intricate logos and detailed graphics, where every line and curve needs to be accurately reproduced on the final product.

Additionally, selecting the right DTF transfer sheets plays a crucial role in maintaining color vibrancy and detail. High-quality transfer sheets are designed to bond strongly with various fabric types, preventing smudging or fading over time. For clothing brands looking to embellish their apparel, this precision and quality are vital for maintaining brand identity and customer satisfaction.

DTF (Direct to Fabric) T Shirt printing offers a precise and high-quality method for custom designs. By understanding the application process, preparing your workstation, and mastering transfer techniques, you can achieve outstanding results every time. With these steps as your guide, you’re ready to take on DTF T Shirt printing projects with confidence, creating vibrant and long-lasting designs that will impress.