Understanding DTF T-shirt printing costs involves considering design complexity, fabric type, color usage, special effects, setup time, and material/labor expenses. Pricing strategies, including value-based pricing and dynamic pricing based on demand and competition, are crucial for success in the DTF market, tailored to target audience behavior and price sensitivity.

“Unleash your creativity in the thriving DTF T-shirt printing industry by mastering custom order pricing. This comprehensive guide navigates the intricacies of setting competitive rates, ensuring profitability while meeting client expectations. From unraveling DTF printing costs—dipping into material, labor, and equipment factors—to employing strategic pricing models, you’ll gain insights for market success. By understanding your expenses and leveraging effective pricing strategies, you’re poised to leave a lasting impression in the dynamic world of DTF T-shirt printing.”

- Understanding DTF Printing Costs: Factors to Consider

- Calculating Material and Labor Expenses for Custom Orders

- Pricing Strategies for Competitive DTF T-Shirt Market Success

Understanding DTF Printing Costs: Factors to Consider

Understanding DTF Printing Costs: Factors to Consider

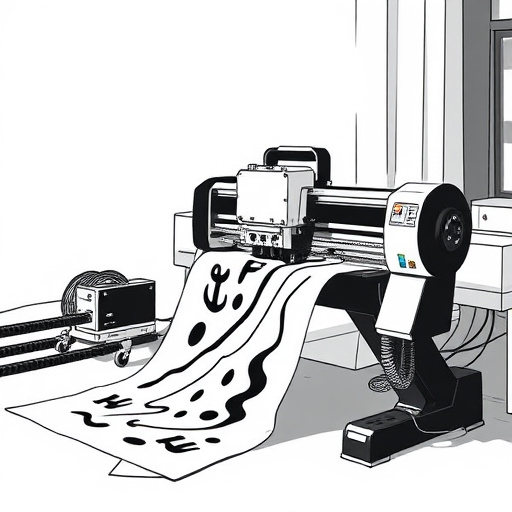

When pricing custom orders for DTF (Direct to Film) T shirt printing, it’s essential to consider several factors that influence the overall cost. The primary considerations include the size and complexity of the design, the type of fabric, the number of colors used in the print, and whether any special effects or finishes are required. For instance, intricate designs with multiple colors tend to be more expensive than simple ones, while light fabrics like cotton may require specific DTF printing techniques that can add to the cost compared to heavier materials like polyester.

Additionally, the setup time for each order should be factored in, as it varies depending on the complexity of the design and the number of print runs. Setup costs can significantly impact the final price, especially for direct to film personalized hoodies or other custom items. Understanding these variables allows printers to offer competitive pricing while maintaining profitability, ensuring satisfaction for both businesses and customers alike in the DTF for t-shirts market.

Calculating Material and Labor Expenses for Custom Orders

When pricing custom DTF T-shirt printing orders, accurately calculating material and labor expenses is paramount to ensuring profitability while remaining competitive. For each custom order, start by considering the cost of the DTF heat transfer paper, which varies based on quality, brand, and quantity purchased. Next, factor in the price of ink or dye used for printing, keeping in mind that different colors and designs may require more or less material.

Don’t overlook labor costs involved in creating the custom design, setting up the press, and applying the cold peel DTF transfers to the shirts. This includes the time spent on design preparation, press operation, and post-printing quality control checks. Additionally, consider overheads such as rent, utilities, and employee salaries when determining your pricing structure for bulk DTG shirt production.

Pricing Strategies for Competitive DTF T-Shirt Market Success

In the competitive world of DTF T Shirt Printing, pricing strategies play a pivotal role in achieving market success. To stand out, it’s essential to balance cost-effectiveness with perceived value, considering both production and material costs. One effective approach is value-based pricing, where you set prices based on the unique features and benefits your custom orders offer. For instance, emphasizing the use of high-quality, vibrant inks in your dtf printing for light fabrics can justify a premium price point. Additionally, offering fast turnaround times or personalized designs can add value to your services, attracting customers who appreciate these extras.

Another strategy is dynamic pricing, where you adjust prices based on market demand and competition. During peak seasons or when new trends emerge, prices may increase due to higher material and labor costs. Conversely, off-peak periods might offer opportunities for competitive pricing to attract customers. Understanding your target audience and their purchasing behavior is crucial; they may be more price-sensitive or willing to pay a premium for specific designs or technologies like heat press applications, allowing you to tailor your pricing accordingly.

When pricing custom DTF T-shirt orders, balancing material costs, labor expenses, and market trends is key to success. By understanding the factors that influence DTF printing costs, calculating these expenses accurately, and employing strategic pricing strategies, you can ensure your business remains competitive in the dynamic DTF T-shirt market. Remember, a well-priced order not only covers costs but also attracts customers and fosters growth.